Hinged Floating Bulkhead Saves Time, Money on Hydro Projects

When a dam needs maintenance, operators need to get the water away from the structure so the work can be done. Achieving dry working conditions can be difficult and time consuming. The hinged floating bulkhead has proved to be a safe and speedy way to get the water out and repairs started.

This dewatering system significantly reduces the owner’s costs, provides a safe work environment, and efficiently uses resources. This bulkhead variant has been particularly valuable in dewatering tainter gates for rehabilitation and testing.

What Is a Hinged Floating Bulkhead?

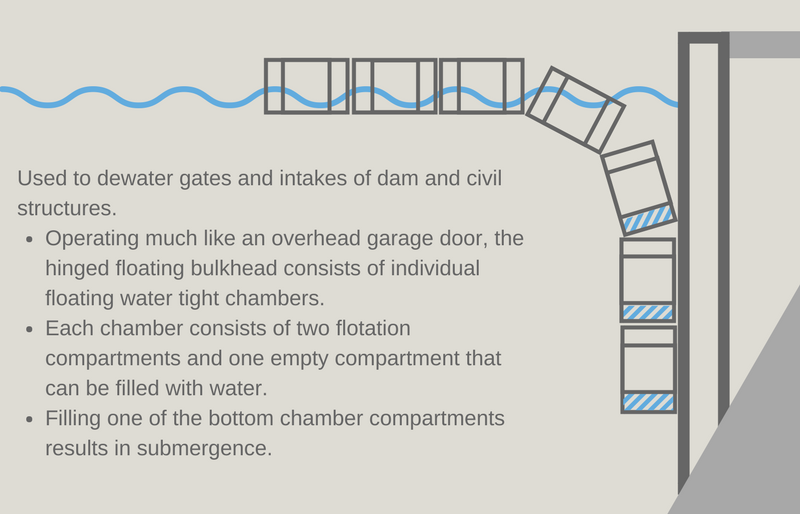

The hinged floating bulkhead consists of individual floating chambers, or caissons, that are pinned together at hinges. Each caisson consists of compartments that are used for flotation of the bulkhead.

How Is It Submerged?

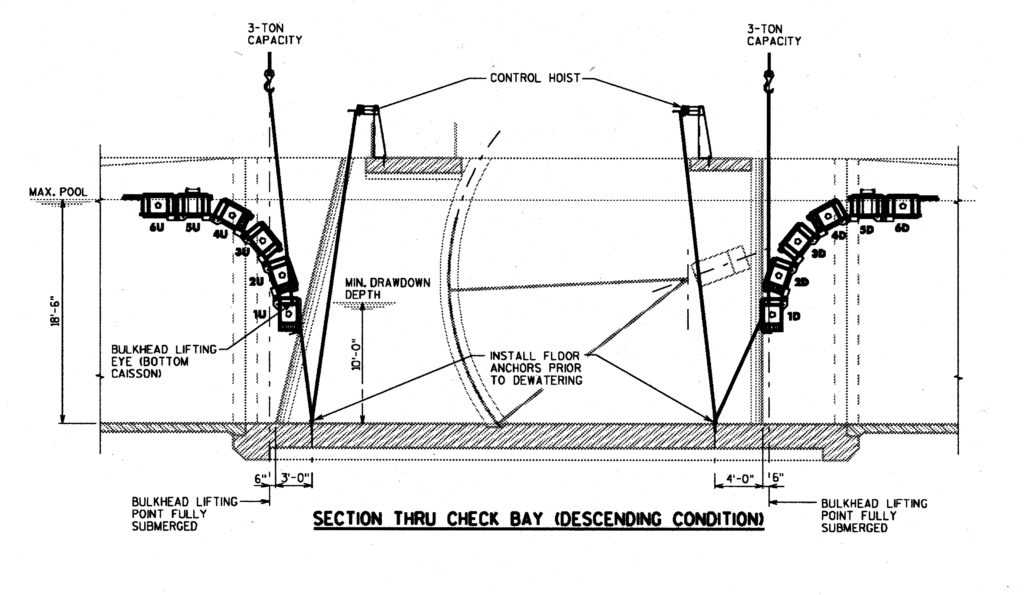

Using changes in buoyancy, the hinged floating bulkhead operates much like an overhead garage door. When all of the caissons are empty, the assembly floats on the surface of the water. As empty segments of the lower caissons are filled with water, the entire unit starts to submerge one segment at a time. The water on the upstream side of the bulkhead holds it securely in place, making repairs and inspection safe.

How Is It Removed?

To remove the bulkhead, the caissons are drained and plugged. Then the space between the bulkhead and the gate is flooded. Once this space is filled and an equilibrium is met on either side of the bulkhead, the assembly will start to float upward until it’s again floating on the water’s surface.

Why Choose a Hinged Floating Bulkhead?

- It protects your structure and limits unnecessary repairs. By using buoyancy, only a small percentage of the bulkhead’s actual weight rests on the intake or spillway.

- It is easier to transport than conventional bulkheads. The individual caissons can be loaded onto a flatbed truck for site-to-site transport. Once at a site, the segments can be launched in shallow water, connected while floating, and pulled by a small boat to the intake or spillway.

- It reduces hydro owner costs. Use of a hinged floating bulkhead significantly reduces owner costs when compared to conventional bulkheads.

- It simplifies the installation and removal process. Because these bulkheads are easy to maneuver and simple to set up, they can be assembled and removed in as little as one day.

The hinged floating bulkhead was developed in 1987 by Xcel Energy and Ayres Associates engineers. Since its initial development, the innovative system has been used at projects across the nation to safely, efficiently, and cost-effectively dewater spillway gates and powerhouse intakes.

For more information about our work with hinged floating bulkheads, check our River Engineering + Water Resources projects.

Post a comment: