Five Dam Engineering Terms That Hold Water

Most of us are familiar with dams and their basic function, but what about everything else that falls under the water resources umbrella? We can’t cover them all here, but let’s look at some not so weir-d words engineers use to describe some pretty practical structures.

Most of us are familiar with dams and their basic function, but what about everything else that falls under the water resources umbrella? We can’t cover them all here, but let’s look at some not so weir-d words engineers use to describe some pretty practical structures.

What’s a Weir?

A weir is generally part of the dam, and water usually flows over the top of the weir. The most common type of weirs are fixed crest weirs, meaning the weir’s elevation does not change. There are many types of weirs: sharp crested weirs, broad crested weirs, ogee shaped weirs, V notch weirs, and labyrinth weirs, to name a few. Different types of weirs can pass more or less water, depending on their shape and design, and engineers select a weir design based on project’s need.

A weir is generally part of the dam, and water usually flows over the top of the weir. The most common type of weirs are fixed crest weirs, meaning the weir’s elevation does not change. There are many types of weirs: sharp crested weirs, broad crested weirs, ogee shaped weirs, V notch weirs, and labyrinth weirs, to name a few. Different types of weirs can pass more or less water, depending on their shape and design, and engineers select a weir design based on project’s need.

Common Uses of Weirs:

- Spillway Capacity: Changes in a weir’s shape make it possible to increase a dam’s spillway capacity without increasing the size.

- Flow Measurement: With control over the variables involved, hydrologists can measure the flow rate of a channel.

- Controlling Invasive Species: Because they can cover the horizontal length of a river, they can prevent the spread of invasive species upstream by creating a height barrier certain invasive species cannot get over.

Using the Hinged Floating Bulkhead

The hinged floating bulkhead was developed in 1987 by engineers at Xcel Energy and Ayres Associates. Since its initial development, the innovative system has been used at projects across the nation to safely, efficiently, and cost-effectively dewater spillway gates and powerhouse intakes.

This bulkhead variant consists of individual floating chambers, or caissons, that are pinned together at hinges. Each caisson consists of segmented compartments. Some of the compartments are airtight and used for flotation, while others are intended to be flooded and filled with water to “sink” the bulkhead. The bulkhead is floated into place in front of the gate that needs to be dewatered. As determined by the size of the bulkhead, a predetermined number of caissons and chambers are flooded, sinking the bulkhead into a vertical position, where it is then floated up against the pier noses. The gate area can then be dewatered.

This bulkhead variant consists of individual floating chambers, or caissons, that are pinned together at hinges. Each caisson consists of segmented compartments. Some of the compartments are airtight and used for flotation, while others are intended to be flooded and filled with water to “sink” the bulkhead. The bulkhead is floated into place in front of the gate that needs to be dewatered. As determined by the size of the bulkhead, a predetermined number of caissons and chambers are flooded, sinking the bulkhead into a vertical position, where it is then floated up against the pier noses. The gate area can then be dewatered.

Sometimes owners of dams need to use a bulkhead to test a gate to make sure it will fully open. Using a bulkhead, the gate can be fully opened, but a significant volume of water is not lost from the reservoir. In other cases a bulkhead may be installed for an extended period of time to dewater a gate and allow repairs to be made to the gate.

Stopping Water With Stoplogs

As the name suggests, stoplogs are individual beams that are stacked one on top of the other in a premade slot as part of a gate or water channel. Stoplogs are often made of wood but can also be fabricated from steel, aluminum, or even concrete.

Water level and flow rate can be adjusted by adding or removing stoplogs. Stoplogs are great during periods of low flow to either raise the reservoir level by adding logs or lower the reservoir by removing logs. During high flow events stoplogs can be difficult to remove, so they typically are not used to increase spillway capacity. Stoplogs are often removed by hand, or sometimes a mechanical lifter is employed to aid in removing larger stoplogs.

Water level and flow rate can be adjusted by adding or removing stoplogs. Stoplogs are great during periods of low flow to either raise the reservoir level by adding logs or lower the reservoir by removing logs. During high flow events stoplogs can be difficult to remove, so they typically are not used to increase spillway capacity. Stoplogs are often removed by hand, or sometimes a mechanical lifter is employed to aid in removing larger stoplogs.

Chicken or the Egg; Dam or Cofferdam

In this instance it was probably the cofferdam that came first. Cofferdams are temporary. They make it possible to create a dry space within a water channel, or even a body of water, allowing for the construction of new structures. They can be made out of materials ranging from earth to steel sheet piling; some are even inflatable.

If a dam were being constructed in a river, typically a cofferdam would be installed upstream and downstream from the work site. After creating an alternative route for the water to flow downstream, the water in between the cofferdams could be pumped out, leaving a dry work environment. After construction is complete, the cofferdams can be removed, allowing the river to flow in its normal channel.

If a dam were being constructed in a river, typically a cofferdam would be installed upstream and downstream from the work site. After creating an alternative route for the water to flow downstream, the water in between the cofferdams could be pumped out, leaving a dry work environment. After construction is complete, the cofferdams can be removed, allowing the river to flow in its normal channel.

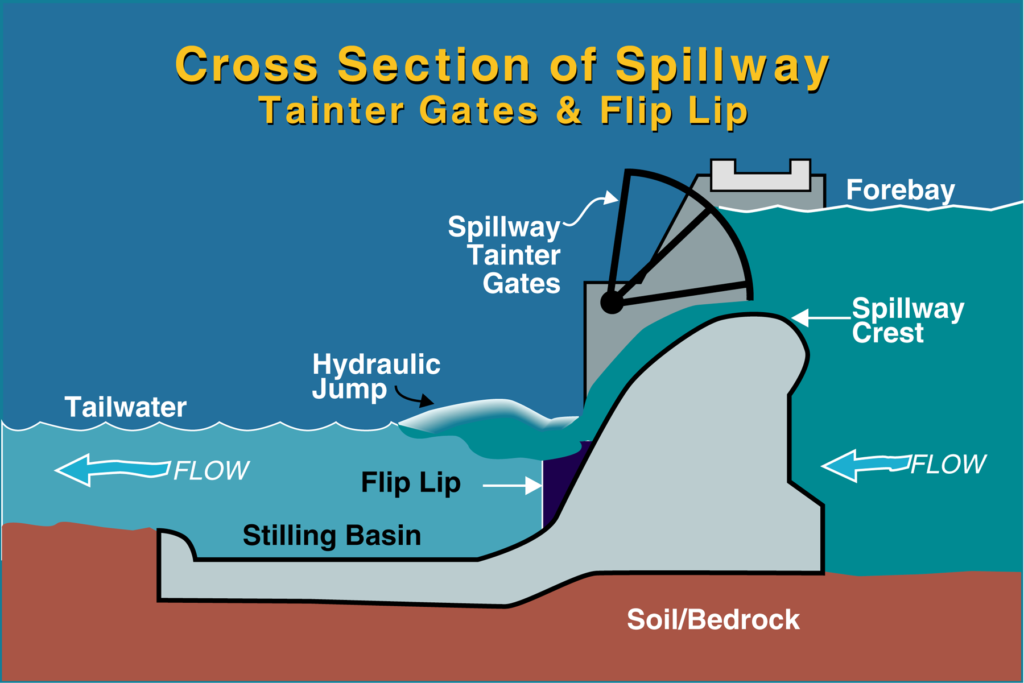

Understanding the Tainter Gate

Many types of gates are used in dams. One is called a Tainter gate, named for Wisconsin structural engineer Jeremiah Burnham Tainter, who invented the gate in 1886. Tainter gates consist of a curved upstream skin or plate that is connected to arms that go back to a trunnion pin. Because of the way the forces act on the gate and are transferred to the trunnion pins, they take relatively little force to open and close.

Dams often consist of numerous Tainter gates, and the gates are opened during flood conditions to increase spillway capacity. During times of low flow the Tainter gate can be “cracked” open, passing a minimal amount of flow under the gate. When reservoir levels rise, the gate is opened more, thereby passing more flow.

Dams often consist of numerous Tainter gates, and the gates are opened during flood conditions to increase spillway capacity. During times of low flow the Tainter gate can be “cracked” open, passing a minimal amount of flow under the gate. When reservoir levels rise, the gate is opened more, thereby passing more flow.

For more information, check our water resources services page.

Post a comment: