What is Computational Fluid Dynamics/3D Hydraulic Modeling?

By Matthew Hickox, PE

By Matthew Hickox, PE

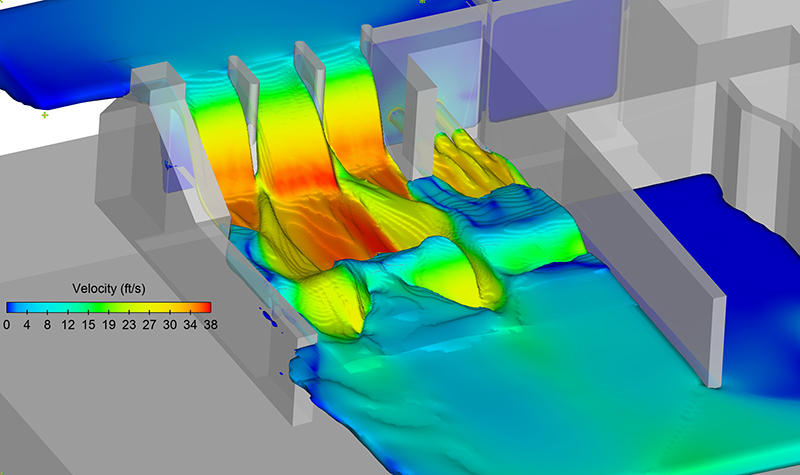

Computational fluid dynamics (CFD), also known as three-dimensional (3D) hydraulic modeling, is a practical way to predict and visualize how water flows in real-world conditions – including in rivers, stormwater structures, and wastewater systems. CFD solves fundamental flow equations that describe how physical laws govern fluid motion. It also provides detail and insight that one-dimensional (1D) and two-dimensional (2D) hydraulic models cannot deliver by resolving the flow in three directions. Simply put, CFD delivers the practical benefits of physical modeling in a reasonable time and budget.

In its early stages, and until recently, CFD was cost prohibitive and only used for very large projects to take advantage of its increased accuracy. But with technological advancement the price has come down considerably, opening the door for smaller communities to take advantage of this cutting-edge analysis.

What About 1D and 2D Hydraulic Modeling?

1D and 2D hydraulic models are effective tools for large-scale, hydraulically straightforward applications. We have pioneered and championed 2D hydraulic modeling’s practical implementation, and it has become the method of choice for many design applications. However, 2D modeling is not the best solution for certain complex hydraulic problems.

In these cases designers have historically either accepted undefined hydraulic uncertainly or have used physical modeling. High uncertainty requires conservative (potentially overbuilt) designs, or it could result in underperforming solutions. Physical models can be reliable but are often prohibitively expensive and time-consuming.

Examples of CFD’s Civil Engineering Applications

Of the many applications for CFD, here is a sampling related to civil engineering:

- Aquatic organism passage (AOP)

- Dam structures

- Decision-making demonstrations

- River features

- Sediment transport and scour

- Stormwater best management practice devices

- Stormwater structures

- Wastewater treatment systems

- Water treatment tanks and processes

Benefits of Computational Fluid Dynamics?

When considering which hydraulic model is the best match for a given project, there are generally four considerations:

- Project risk and uncertainty

- Hydraulic complexity

- Design cost

- Design time

CFD isn’t going to make sense for every project, especially not if it’s simple, hydraulically speaking, and if the budget is limited. But for a complex project that comes with a lot of risk and uncertainty, CFD can be a more affordable option compared to physical scale models and full-scale prototypes, while also providing more data than 1D/2D hydraulic modeling. This means less impact on budget and a shorter design schedule while also reducing the uncertainty in the final design.

For more information regarding CFD or the hydraulic engineering services we offer here at Ayres, please contact Matthew Hickox, PE.

Post a comment: