Unidirectional Flushing Scrubs Water Mains, Fire Hydrants

To maintain their water supply systems, communities schedule routine water main and fire hydrant flushing, which removes sediments, deposits, and biofilm buildup from water systems and improves overall water quality.

A unidirectional flushing program (UDF), however, takes those routine flushes a step further.

How Does Unidirectional Flushing Work?

In general, UDF involves using clean water to flush the system from the source outward by isolating portions of the distribution system to achieve water flow in one direction.

UDF sequences are designed to achieve high velocities in target pipes to properly remove deposits and debris from the water mains and flush them from distribution piping. A specific sequence of valve closings and hydrant openings is used to create higher water-flow velocities to scour, or “scrub,” the pipes clean. For example, flushing by simply opening a hydrant may create a flow of 2 feet per second in the water main; however, by systematically closing valves, the flow will often reach 6 to 8 feet per second in the water main.

The water that comes out of hydrants during this process isn’t always pretty, but that’s a sign that the scouring is working.

The Model Behind Unidirectional Flushing

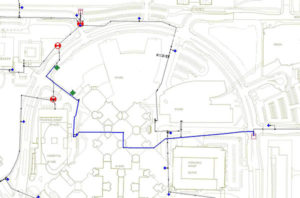

To figure out the proper flow patterns to use during unidirectional flushing, a model of the water system must be created or already available. Modeling requires knowledge of system configuration, water supply, pressures, basic usage information, and a base map. Existing, compatible water system models may be used for creating the UDF model.

To figure out the proper flow patterns to use during unidirectional flushing, a model of the water system must be created or already available. Modeling requires knowledge of system configuration, water supply, pressures, basic usage information, and a base map. Existing, compatible water system models may be used for creating the UDF model.

At Ayres Associates we use WaterGEMS software for the modeling. In most instances, field flow data must be obtained to verify and calibrate model results. Once a model is created and running accurately, our municipal engineers can develop a UDF.

Why Is Unidirectional Better?

UDF is a best management practice that cleans and maintains a community’s water distribution piping.

A UDF program offers many benefits:

- Reduces sediment, biofilm, and corrosion products.

- Improves water quality.

- Improves the capacity of existing pipes.

- Decreases frequency of flushing.

- Improves operation of the water system.

- Can use less water than conventional flushing operations.

- Identifies inoperable valves and hydrants.

- Reduces customer complaints.

UDF: More and More Communities Go With the Flow

According to a unidirectional flushing paper published by the American Water Works Association, distribution system deficiencies continue to be responsible for more than 25 percent of waterborne disease outbreaks in the United States each year. UDF is being used by a growing number of utilities as a cost-effective way of improving and preserving water quality in the distribution system.

Craig Schuh is a municipal engineer in our Green Bay area office.

Post a comment: